CLS621 Printer Errors

This knowledge base article shows you the common CLS621 Printer Errors encountered when producing number plates. When your printer detects a problem, its control panel lights up to indicate the issue. But being a simple machine, any problem can easily be found and fixed. Below you will find common errors listed alongside their solutions.

Paper mentioned throughout this article refers to any type of compatible media. Especially since these are label printers by default, designed for paper rolls. If you have any other type of error, please check your guide or the manufacturers Citizen Website before getting in touch.

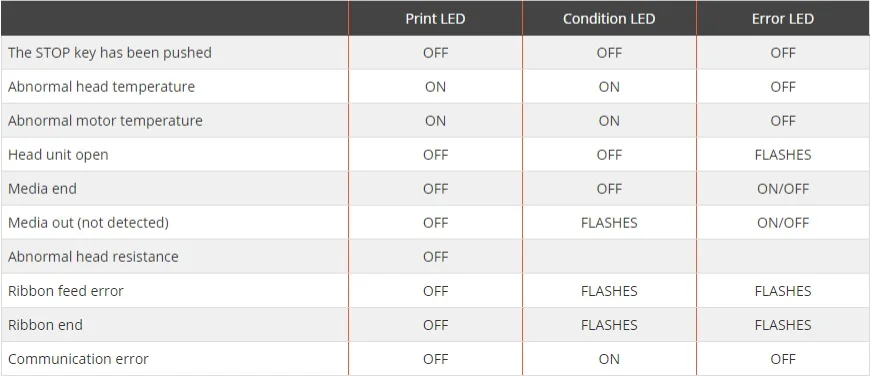

CLS621 Printer Errors & Alarms

When your CL-S621 Printer detects a problem it sounds an alarm and flashes its lights. Below we have listed a range of common print problems, alongside their light status. You can use the lights location and colour to help identify the issue.

Note: Silence the printers alarm by pressing the stop button. Press it again to resume printing.

Troubleshooting Errors

Once you know what problem you have, you can then start to put it right. The troubleshooting information below, shows how to fix common problems found when using these printers.

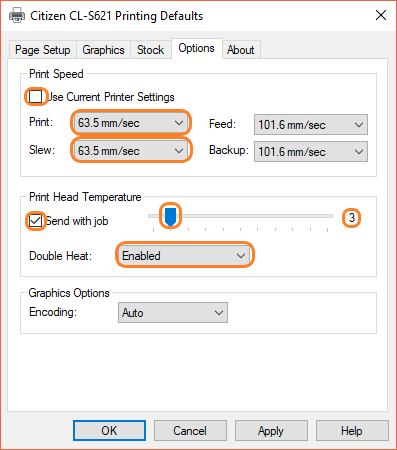

Abnormal Temperature

Overheating can usually be solved by providing adequate ventilation and space around the printer, see our operating conditions guide. If you are getting abnormal print head temperatures don’t forget to ensure it’s clean. Then check your printing defaults temperature and speeds are the same as the values shown above.

Print Head Open

Print Head Open alarms occur when the print unit has not been locked down, this can stop operation. To fix, open the printers top cover then lift the unit all they way up. Quickly check nothing is trapped underneath, then push the lever (A) down until its clicks and locks. Replace the printers top cover when you’re finished.

Ribbon Errors

Fix Ribbon End errors by replacing it when an end is detected by the printer. Or in the case of a “Ribbon End” false positive, check the cores are fitted properly or the tension settings. This error can also be shown when a ribbon is fitted the wrong way.

Ribbon Feed Errors occur when it has not been installed correctly or is twisted and wrinkled. Always ensure the winding cores are fully inserted into the cradle and are configured as ink out. A loose or wrinkled ribbon will need the cores jiggled to remove any creases and slack. If errors persist check the tension and media adjustment controls, refer to your manual for the settings.

Media Errors

The simplest media problem is when the printer detects it’s empty, simply re-stock to solve this. Additionally, the printers sensor may be looking for a notch or a starting mark. When loading a new roll, always use the feed button on the control panel to move to the start of a panel.

Need Help?

This is a quick article on CLS621 Printer Errors, refer to your user guide for more details. Or for further assistance, contact our tech support & customer service team for help. For ribbons, supplies or plate media for your printer, try our online NP-Shop – trade account required.

Note: If your reflective isn’t being pulled through the printer, check the CLS621 Media Tray is seated correctly.